ZWM WARAKSA: How to invest in manufacturing in the metal industry?

The continuous growth of the economy and industry is driving the demand for metal structures. We encounter them at every turn – from park benches to the large skeletons of load-bearing halls. The market is dynamic and growing rapidly. The prerequisite for success in this industry is not only a good product, but the durability of the detail and the aesthetics of the workmanship. How do we ensure that these challenges are met? Are short production runs an obstacle to robotisation?

About the company

ZWM Waraksa is a well-established, family-owned company with a 30-year tradition that specialises in the metal construction industry, both domestically and abroad. The company operates as a service provider and focuses on long-term cooperation with business partners.

The key product groups manufactured include gates, brackets, fences, balustrades and luggage trolleys. The company produces galvanised or painted components – according to customers’ wishes. The offer also includes services such as CNC machining, laser cutting and assembly. With many years of experience in welding and the quality of the constructions made, ZWM Waraksa systematically expands its operations, boldly introducing technological innovations.

One of types of key product groups

ZWM Waraksa adapts perfectly to the needs of the market. It focuses on continuous development and production optimisation. These pillars led the company to take on the challenge of automating production. ASTOR, one of whose branches is based in Gdańsk, was chosen as the contractor. The Welding Competence Centre operating there consulted on the robotisation project and supported its preparation and implementation at ZWM Waraksa.

Genesis of welding robotisation

In June 2021, a new hall was developed at the plant for the first station with a Kawasaki Robotics welding robot. The gantry system was automated, overhead cranes were installed for easier handling of heavy workpieces, and transport trolleys were implemented for transporting large metal structures.

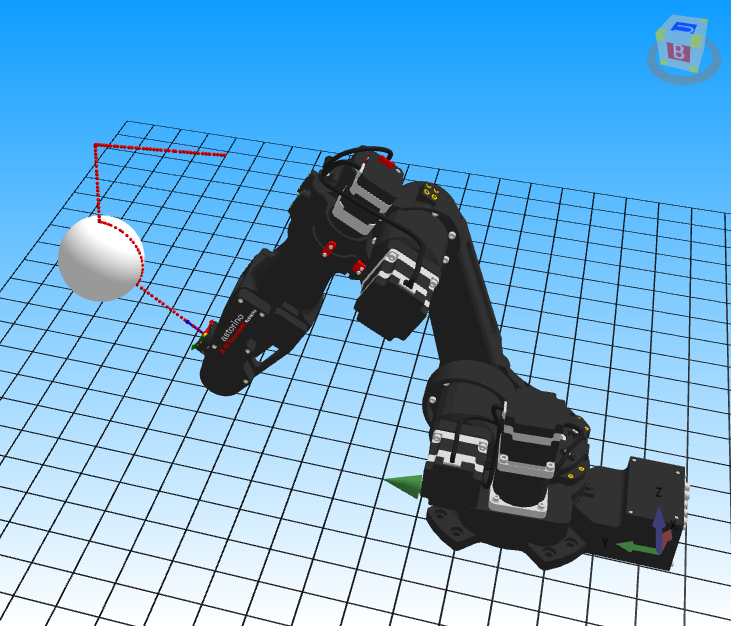

Kawasaki Robotics welding station with positioners

“Due to the company’s service profile and the variety of parts produced, robotic welding required the involvement of our team in adapting production processes. The investment in the first Kawasaki robot station has improved productivity by an average of 50%. This has enabled us to fulfil even more orders. After six months, we purchased a second station. We started to scale up robotisation more and more,” says Artur Waraksa, CEO of ZWM Waraksa.

The implemented welding cell was individually adapted to the customer’s specific production. It is characterised by versatility in the choice of welding technology and flexibility in terms of changeover to any part.

“The first universal robot cell is equipped with two positioners (turntables) working with a Kawasaki welding robot. The workstation is suitable for the production of various parts in any material,” – says Szymon Habecki, Project Manager on the ASTOR side.

Robotisation of welding increased the quality of welds on metal structures and reduced the time needed to produce the final element.

The benefits of robotisation

The benefits of this prompted company president Waldemar Waraksa to deploy another Kawasaki Robotics robot in January 2022, 7 months after the first station.

This latest welding cell was created for machining large-volume parts weighing up to 1.5 tonnes. The workstation consists of a Kawasaki Robotics robot, a linear track to move the robot and welding fixtures.

The use of an additional linear track made it possible to create two 6-metre working fields, be translated into smooth workpiece changeovers and continue production. Specially prepared troughs allow for convenient loading and unloading of the product. Ease of use is ensured by an application on the operator panel.

Robotisation has significantly increased safety and comfort for employees. Employees feel safe working at the welding cells, thanks to being shielded by pneumatically controlled shutters, as well as the anti-collision system used and the responsive software informing the operator of any changes in the robot’s operation.

All these changes have improved the working conditions of those employed at ZWM Waraksa. Contact with modern technologies has enabled professional development and increased the competence of employees. As a result, operators supervise the process and control its effects, while engineers create welding programmes with the support of ASTOR specialists.

Robotised welding

Summary

Robotisation of the welding workstations at ZWM Waraksa makes it possible to maintain the dynamics and fluidity of production, increase employee safety, and undertake more orders for business partners. The company’s management does not stop at making revolutionary changes and optimising processes. It is already planning to expand the production halls and develop new space in order to fulfil further contracts.

Contact us

Are you looking for an authorized distributor of Kawasaki Robotics in your country? Contact us!