IMSAT Robotics: Kawasaki Robotics robotic workstation for the film laser cutting of automotive dashboard decorative components

Robotization in the automotive industry

In the automotive industry, precision and speed of detailing are crucial for overall production and for increasing competitive advantage. Companies in the automotive industry have the most robots installed compared to other sectors of the economy. They are used for welding, painting, handling and many other applications.

Kawasaki Robotics robots in the automotive industry

A Romanian manufacturing company with orders from the automotive sector has decided to invest in a robotic workstation for laser cutting.

A Kawasaki Robotics RS050N workstation

The project was undertaken by IMSAT, a company with 60 years’ experience in the field of automation and robotics. IMSAT is the authorized distributor of Kawasaki Robotics in Romania.

The laser cutting Kawasaki Robotics robot

Laser cutting is a dangerous process for humans, which is why this process is often robotized so that the operator can supervise the process from a safe distance while the robot precisely performs the most difficult and dangerous part of the work, i.e. operating the workpiece in the hazardous area.

Details for laser cutting preparation

In addition, the high quality standards of the automotive industry required a robot with very good cycle time performance and very high accuracy and repeatability.

Kawasaki Robotics RS050N was chosen for this application because of its high dynamic performance and accuracy of +/-0.06 mm.

This robotic station performs the laser cutting of excess thermoformable film from decorative automotive dashboard parts. The Kawasaki Robotics RS050N robot manipulates a small part while the large laser head is mounted in the holder.

Kawasaki Robotics RS050N during a laser cutting operation

Kawasaki Robotics RS series robots are a series of industrial robots with small to medium payloads. Using the latest materials and a highly refined design, they are lightweight and fast, and 17-bit encoders provide very high accuracy. These are high speed industrial robots. They are characterized by high dynamics of movement, have a payload of 3 kg to 80 kg and a reach of 620 mm to 3150 mm.

Implementation of laser cutting project

The complexity of this project was due to the 3D geometry of the trajectory and the fixed cutting point, with the need for the Kawasaki Robotics RS050N robot to move the workpiece relative to the laser beam.

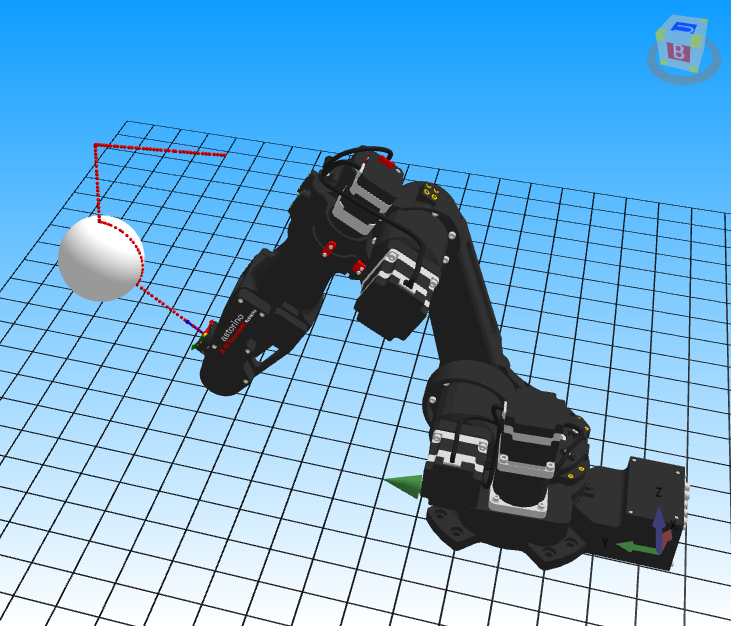

These challenges were overcome by IMSAT’s specialists using dedicated K-Virtual software to generate the robot’s trajectory.

K-Virtual is an offline software from Kawasaki Robotics that allows for the accurate design of the application and generate robot movements prior to actual implementation. Tests and simulations performed in K-Virtual allow the application to be implemented much faster in a real production environment.

The application also uses two functionalities for Kawasaki Robotics robots:

- The Tool Changer function allows automatic tool changing according to the workpiece.

- The Fixed tool function allows the robot to move relative to the tool held in a fixed position.

Other applications of this system

The Kawasaki Robotics robot implementation with K-Virtual software described above is applicable to any industry, in any application, where short cycle times and high accuracy of an industrial robot are required.

We have 60 years of experience in the robotics industry. Our experts have specialized know-how, they know the automotive industry and its requirements. We deliver solutions that provide high– performance applications and significantly improve process efficiency in every industry and manufacturing sector.” – Mihai Stoian, Manager of

Watch the video and see how the robotic cell implemented at this facility is used to laser cut the excess foil of the decorative parts of the car’s dashboard:

Contact

Imsat is a long-standing partner of Kawasaki Robotics and ASTOR in the field of robotisation. Currently, it focuses mainly on the implementation of robotic solutions in the metal and automotive industries. If you are interested in similar solution, please contact us.