Business costs and CO2 emissions taxes: robotization as the key to energy savings

Growing environmental awareness and commitments arising from climate policy are leading more and more companies to seek ways to reduce operational costs by lowering emissions and managing energy more efficiently. In this context, the robotization and automation of production processes are becoming one of the most promising solutions.

Increase in Co2 emission costs and Impact on Enterprises

The price of CO2 emission allowances is systemically rising. In Europe, under the Emissions Trading System (EU ETS), the cost of one ton of CO2 has reached record levels in recent years, exceeding 90 euros per ton (currently hovering around 85 euros). As a result, companies, especially those operating in energy, are facing increasing pressure to implement emission reduction strategies. Rising costs are particularly painful for the manufacturing sector, where energy consumption and greenhouse gas emissions are a significant part of operational activities

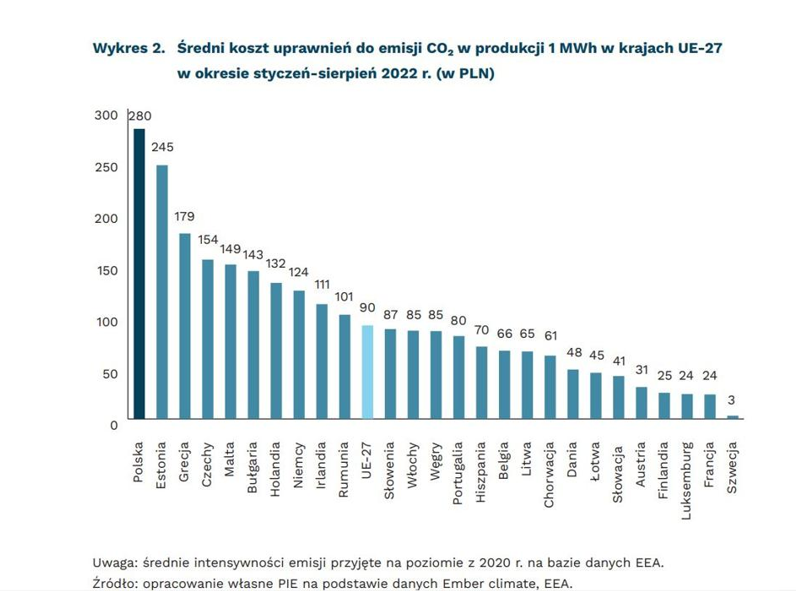

The increase in CO2 emission costs affects not only large corporations, but also medium-sized and small enterprises that are trying to remain competitive on the market. Costs related to emission represent a large percentage of total operating expenses in industries such as heavy industry, cement production, metallurgy, and the chemical industry. The high carbon intensity of Poland’s energy sector, where producing 1 MWh of energy is associated with emissions of over 700 g of CO2, results in higher expenses for emission allowances.

Chart 2: Average cost of CO2 emission allowances in the production of 1MWh in the EU-27 countries in the period January-August 20202 (in PLN).

Note: Average emission intensity assumed at the 2020 level based on the EEA database

Source: PIE’s own study based on Ember climate, EEa

Increasing energy efficiency as a cost reduction strategy

Companies are increasingly investing in energy efficiency to reduce energy consumption and lower costs. Reducing energy use not only helps decrease operational expenses but also limits CO2 emissions, which in the long term leads to lower expenses related to emission fees. There are several strategies that companies can implement to improve energy efficiency:

- Optimization of production processes – implementing modern technologies, such as advanced energy management systems, which monitor and automatically regulate energy consumption in different parts of the facility.

- Equipment modernization – replacing older machines with newer , more energy-efficient models. Many industrial devices and machines are now available in low-energy-consumption versions.

- Use of renewable energy – installing solar panels or wind turbines on-site can significantly reduce energy costs and contribute to emission reduction.

Robotics as a tool for reducing costs and CO2 Emissions

One of the most effective ways to lower energy consumption and reduce operational costs is robotization. Industrial robots, programmed to perform precise tasks, can operate more efficiently than traditional production methods, reducing energy usage at various stages of manufacturing.

In addition, robotics enables:

- Minimized energy consumption through automation of repetitive processes – robots can operate continuously for long hours while using less energy compared to manually operated machines.

- Reduction in production costs – robots carry out tasks with high precision, which minimizes the need for corrections, saving both time and energy

- Improved production management – robots equipped with sensors and AI technologies can optimize the production process, reducing the use of raw materials and energy.

Examples of robotics applications in industry

The automotive industry is one of the best examples of a sector that has significantly benefited from the implementation of robotics to reduce energy costs and CO2 emissions. Using robots for tasks such as welding, assembly, or painting allows for precise material dosing and process control, which reduces waste and energy consumption. As a result, automotive companies can meet emission reduction targets while also lowering production costs.

Robots are also widely used in food and pharmaceuticals industries for tasks like packaging and sorting. Through automation, companies can manage logistics processes more efficiently, which leads to lower energy consumption and reduced emissions across the entire supply chain.

Financial benefits of investing in robotics

Although investments in robotics may seem costly at first, they bring tangible financial benefits in the long term. The reduction of operating costs related to energy consumption and CO2 emissions can significantly increase a company’s profitability.

Moreover, many countries offer grants and tax incentives for companies investing in low-emission technologies, which further reduce the financial charges. In Poland, businesses can take advantage of the robotization relief, which aims to support investments in the automation of production processes, particularly in technologies related to robotics.

Thanks to this relief, companies can deduct from their tax base as much as 50% of eligible costs related to the purchase of industrial robots, peripheral machines, as well as improvements in ergonomics and workplace safety. It also covers expenses for training on robot operation and leasing costs. The relief has been in effect since January 1, 2022, and is available to entrepreneurs paying either PIT or CIT, regardless of the size of the company or industry. As a result, businesses can not only reduce their tax burden but also significantly improve operational efficiency, which represents an important step toward innovation and competitiveness.

Summary: Robotics as a key to sustainable development

Taxes and fees related to CO2 emissions are becoming increasingly burdensome for companies, which must seek new ways to reduce energy consumption and cut costs. Robotics presents one of the most promising solutions, offering businesses the opportunity to lower operational expenses, increase efficiency, and enhance sustainability. With the use of robots, companies can not only reduce their emissions but also adapt to growing regulatory requirements and consumer expectations regarding environmental protection.

For many businesses, robotics is not only a path to achieving sustainable development but also a key to survival in an increasingly competitive market. In the future, as emission costs continue to rise and regulations become stricter, the importance of robotics will only grow and companies that invest in it will gain an advantage over the competition.