Automatica 2025: Four Days of Innovation, Automation, and Inspiration

Automatica 2025 once again confirmed its status as the leading global event for automation and robotics, drawing attention from across Europe and beyond. It was the meeting point for manufacturers, system integrators, engineers, and industry leaders eager to exchange knowledge, share experiences, and present their latest technological achievements. For four action-packed days, the exhibition halls buzzed with energy, offering visitors a unique opportunity to witness the future of industry firsthand.

This year’s edition focused on key trends driving industrial transformation. At the heart of the show were industrial and collaborative robots (cobots), automation of assembly and packaging processes, advanced vision systems, artificial intelligence (AI), production digitalization, Industry 4.0, and the Industrial Internet of Things (IIoT). Sustainable production and energy efficiency were also central themes, reflecting growing global awareness of responsible manufacturing practices.

Special emphasis was placed on production flexibility, human-robot safety, and the integration of AI into industrial automation. With these advancements, production systems are becoming even more autonomous, adaptive, and capable of learning from their environment—empowering companies to respond quickly to market demands and operational challenges.

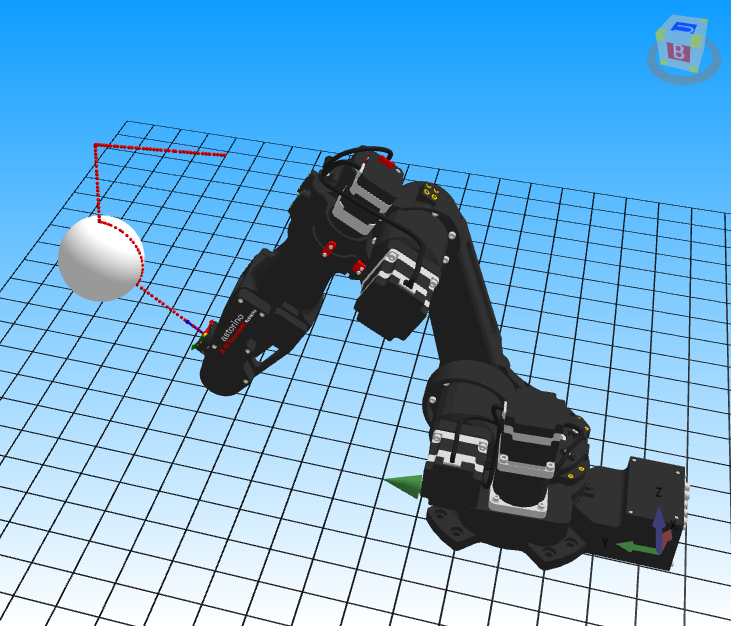

Kawasaki Robotics Astorino – educational robot working as industrial one.

Technology Highlights That Stole the Show

As always, Automatica delivered plenty of exciting product premieres and cutting-edge innovations. Among the highlights were new-generation palletizing robots and heavy-duty handling solutions addressing the logistics automation boom. Next-generation cobots with greater payloads and extended reach also drew significant attention, promising safer and more flexible collaboration with human operators.

Solutions for specialized industries such as food, pharmaceutical, and medical sectors were prominently featured. Advanced AI-powered vision systems showcased their ability to revolutionize quality control, sorting, and real-time decision-making, helping companies improve efficiency while reducing operational costs.

Another notable trend was the growing focus on eco-friendly automation. More manufacturers are embracing energy-efficient drives, lightweight constructions, and smart systems that optimize resource and energy consumption—marking a decisive step towards sustainable industrial growth.

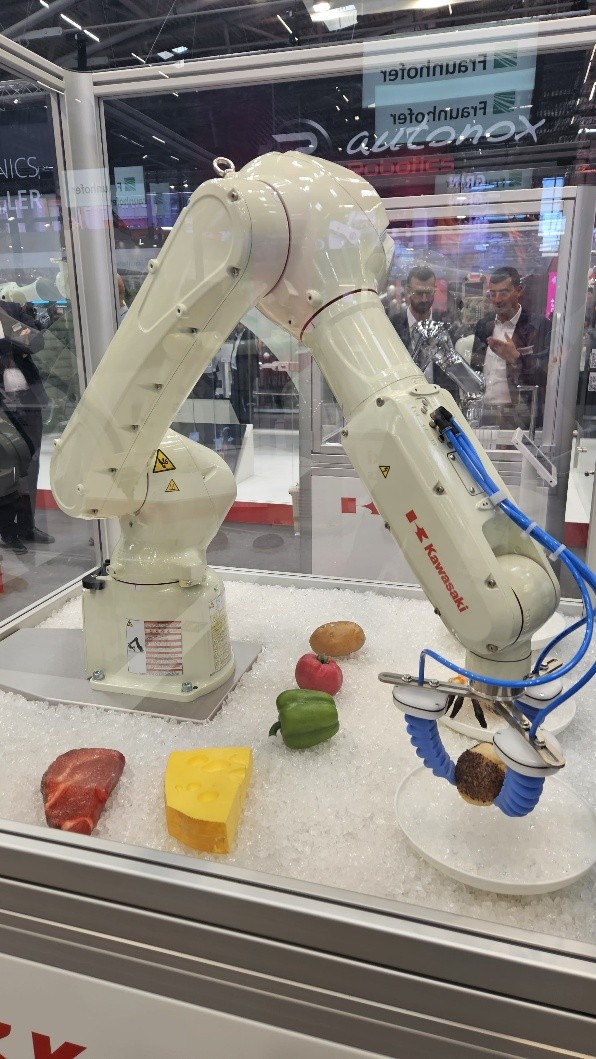

Kawasaki Robotics RF007L- robot designed for food industry which meets hygiene requirements.

Kawasaki Robotics Unveils Four New Game-Changing Models

One of the standout exhibitors this year was Kawasaki Robotics, unveiling four new robots set to hit the market by the end of 2025. The company introduced a diverse range of solutions tailored to meet the evolving demands of multiple industries:

- CP110L – A next-generation palletizing robot from the renowned CP series, now featuring extended reach, optimized speed, and improved handling of heavy loads, perfect for high-throughput end-of-line operations.

- RF007L – A compact and hygienic robot designed specifically for the food industry. Built to meet the strictest hygiene standards, it is lightweight, easy to clean, and ideal for environments requiring frequent washdowns.

- MC006V – A high-precision robot engineered for pharmaceutical and medical applications. Its cleanroom-friendly design ensures compliance with stringent sterility requirements, making it suitable for sensitive production environments.

- CL Series – A collaborative robot (cobot) with an impressive 30 kg payload capacity. This model stands out in the collaborative robotics market by combining human-friendly interaction with real muscle power—enabling safe yet powerful assistance in demanding applications.

Automatica 2025 showcased a clear vision for the future of industrial automation—one driven not only by greater efficiency but also by enhanced flexibility, safety, and environmental responsibility. The next few years promise rapid advancements, as smart, sustainable, and collaborative automation continues to reshape modern manufacturing worldwide.