Robotics as a way to increase competitiveness – UNIA GROUP

How robotic welding stations and integrated production solutions can boost efficiency and strengthen a company’s market position – the Unia Group case study.

Unia Group is a company with a 140-year tradition, specializing in the production of agricultural machinery used for sowing, fertilizing, transport, and storage, among other applications. Since its establishment, the company has been committed to the development of the industry by implementing the latest technologies in the agricultural machines and equipment it produces.

Its four production plants, located in Grudziądz, Słupsk, Brzeg, and Kąty Wrocławskie, manufacture around 25 000 machines annually, with the involvement of nearly 1,000 employees.

“We believe that farmers’ success depends on access to modern and reliable machinery. We create solutions that meet the highest standards, helping farmers increase efficiency and achieve the best results” says Michał Lange, CEO of Unia Group.

The machines offered to farmers by Unia Group are manufactured in Poland. Domestic customers are reached through cooperation with a network of 40 distributors, while thanks to partners around the world, the machines are available in 60 countries on all continents. The equipment, equipped with the latest technological solutions, is developed based on farmers’ feedback and market analyses.

In 2023, Unia Group became part of the Chemirol Group, opening a new chapter in its history. In 2024, the company launched a multi-million investment program that includes the implementation of robotic welding stations, advanced laser systems, and modern machining centers. These investments were complemented by the launch of a state-of-the-art paint shop, setting new standards for quality and production efficiency.

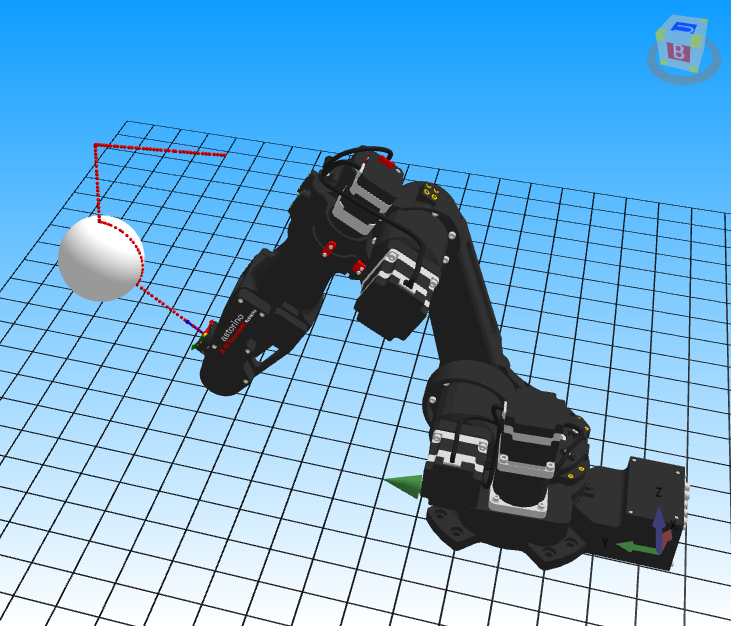

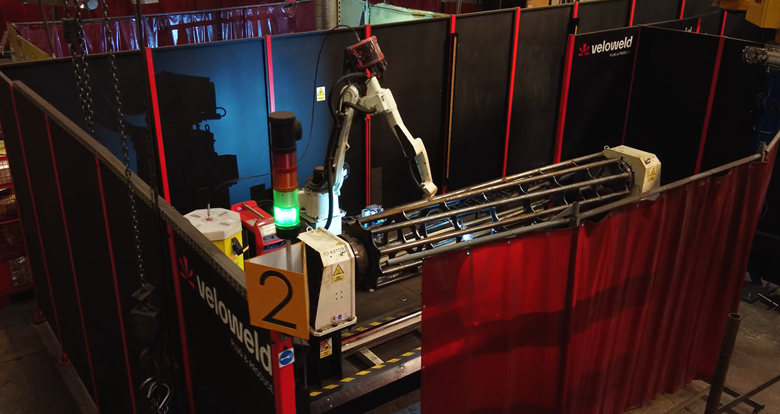

As part of the welding shop modernization project, four advanced robotic welding stations were implemented. Each station is equipped with a welding robot moving along a 10-meter track and two positioners with a maximum load capacity of 2 tons each. To meet Unia’s production challenges, over 50 specialized welding applications were developed, along with dedicated tooling for tack welding and robotic welding processes. An important factor in improving welding quality is the use of real-time path correction systems, which ensure process repeatability. These systems enable precise arc welding, even under variable production conditions.

The project also addressed aspects related to operator support and maintenance operations. The stations were equipped with manual cranes to facilitate the loading of heavy components by operators, as well as an integrated CMMS system for machine maintenance management.

The entire implementation project was supported with full technical assistance at every stage – from the design phase, through installation, to commissioning, and process optimization.

The implementation of modern production technologies and the robotization of welding processes has significantly improved product quality, enabled process optimization, reduced the number of corrections, and shortened order fulfillment times. A key element of this development was the expansion of the machine park, which resulted in a clear increase in the efficiency and productivity of production lines.

“The investments have significantly contributed to increasing the company’s competitiveness and have enabled better cost and resource management,” says Tomasz Soboń, Technical Director of Unia Group.

Robotic workstations are seen within the industry as a source of competitive advantage, as they allow for better control over the so-called technical cost of production. This translates into the ability to manufacture high-quality products faster and at lower costs. This is particularly important for companies operating in global markets and competing with the largest players worldwide.

The implementation of robots at Unia Group has also created opportunities for employees to develop new skills. Today, operators oversee the process and monitor its outcomes, while engineers design new welding programs and tooling. Gaining these new competencies is an investment not only in the employees’ own futures but also in the future of the company. The ability to program robots, combined with the modular structure of the workstations, allows for quick retooling and the launch of new products, enabling continuous advancement of welding automation. Thanks to their acquired skills, Unia Group employees carry out these changes independently, without the need to involve external experts.

The investment proved successful not only because growth is embedded in the company’s strategy but also because Unia Group chose to work with trusted partners.

For over 35 years, ASTOR has been providing advanced solutions for industry in Poland and Central and Eastern Europe. The company specializes in intralogistics systems, automation, digitalization, and production process robotization, supporting businesses in their transition toward Industry 4.0. ASTOR is the distributor of Kawasaki Robotics robots, which were implemented at Unia Group. Another partner in the project is Veloweld, a supplier of robotic welding cells. Both companies closely cooperate with each other.

All indications suggest that the 2024 investments are not the end of the transformation. The next step for Unia Group is to expand its production halls to fulfill new contracts. In the near future, further investments in production automation and robotization are planned.