Palletizing with mixing – a solution for distribution centers

Avon is one of the most well-known cosmetics companies in the world, with a rich history and a unique business model that sets it apart from the competition. For several years, the company has been heavily investing in process automation to enhance efficiency in production, logistics, and customer service.

In Avon’s distribution centers, automated sorting systems and automated guided vehicles (AGVs) are used to facilitate the rapid movement of goods from warehouses to shipping lines.

These technologies:

- speed up order fulfillment and deliveries to customers,

- increase order picking accuracy, reducing the number of errors,

- enable the handling of a larger volume of orders with less employee involvement.

Palletizing automation brings a lot of benefits to the process of preparing goods on pallets. When combined with advanced mixing technology with multi-directional, we will receive process optimization within in the distribution center, which allows for more flexible and efficient order fulfillment. For this reason, Avon decided to further invest in this area, and ASTOR delivered the EtE®flow palletizing system with mixing capability for 12 shipping directions.

Already at the concept stage, performance simulations and a pallet stacking algorithm simulator were prepared. These simulations ensured that before the project even began, the system would meet the client’s quality expectations and provide performance reserves to support future growth in production and sales.

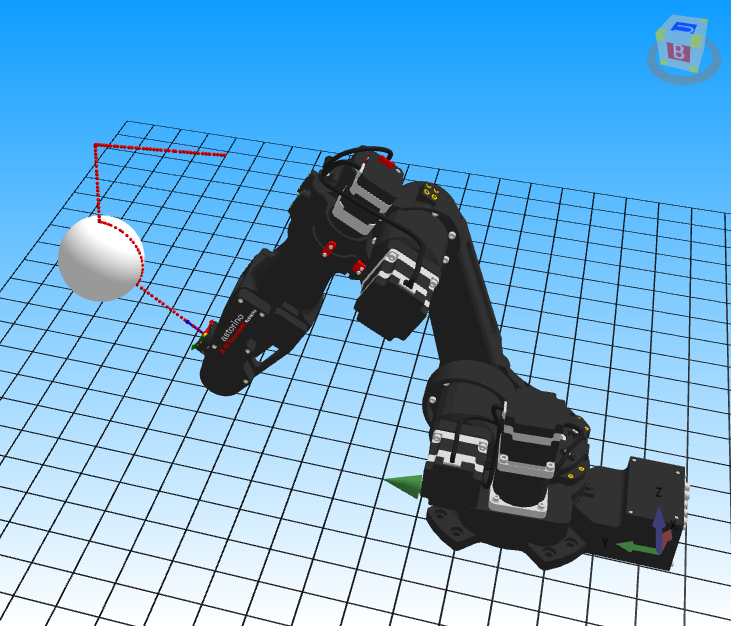

The system consists of two twin palletizing stations for cartons, each capable of handling 6 directions, and includes:

- a Kawasaki Robotics CP180L robot,

- a specially designed flap gripper,

- roller conveyors for transporting cartons and trays,

- pallet positioners,

- buffer zones for half-size cartons,

- a tray stacker.

The process is controlled by two Astraada One Compact PLC controllers. The first one manages the entire station’s operation: the robot, feeders, and roller conveyors. A separate controller is dedicated to operate the tray stacker.

At a single palletizing station, the robot picks up a carton with a flap gripper and places it on a pallet corresponding to the designated shipping direction. An exception is the so-called half cartons, which the robot pairs together before placing them on the pallet. To do this, it uses a commonly known buffer located directly in front of each palletizing bay.

At the logical level, the station’s control system communicates with the client’s database to obtain information about shipping direction of each carton. Additionally, the system uses a special carton stacking algorithm. Based on this algorithm the robot decides which position within the pallet a given carton should be placed. Cartons appear randomly, so the robot built pallet in way that allows placement of every possible carton type while maintaining pallet stability. The pallet is completed when either a weight or height condition for pallet completion is reached.

The palletization’s stations are equipped with barcode scanners and measuring gates, whose task is responsible for measure the height of cartons and reject those that do not reached quality parameters.

The stacker is responsible for building stacks of plastic trays on which certain types of cartons are delivered. The trays are stacked and transported via a roller conveyor outside the station. Behind the stacker, there are three buffer spaces designated for storing the stack of trays. ‘’Error” type of cartons (unreadable barcode, height measurement out of tolerance, incorrect direction) are placed by robot on a conveyor that transports them out of the stations.

For communication between the PLC and the Kawasaki robot controller, as well as with the roller conveyor controllers, the Ethernet/IP protocol is used. The algorithm and program are proprietary solutions developed by the system provider, ASTOR company.

The entire system is complemented by the Astraada PC Terminal HMI panel, which displays a visualization application running directly on the Astraada One controller. Thanks to that, the operators have access to interface for monitoring and configuring the entire system.

The palletizing stations are equipped with a safety system. The first component of this system is CUBIC-S, an additional safety controller from Kawasaki Robotics that monitors the robot’s movements in real time. CUBIC-S prevents the robot from reaching positions outside the designated safety zones. This ensures the safety of the system’s operation by operators.

Palletization’s stations are additionally quipped with electromagnetic safety locks installed at the entrances, also with safety buttons located both inside and outside each station. Pressing a safety button or unauthorized entry into the station triggers an immediate emergency stop of the robot. The processes of pallet replacement and work initiation are described by a startup sequence (resetting the station from both inside and outside), which further enhances the system’s safety.

Each station features its own control and safety system with software that enables ergonomic operation of its functions. As a result, both stations operate completely independently which means that a downtime of one station, due to pallet replacement or maintenance, does not affect the operation of the other.