Benefits of using digital twins of robots or a robotic operation system

Virtual copies of individual robots allow for risk-free testing and programming of production process. They facilitate the start-up of new lines and the retooling of existing one.

Factory developing according to the principles of Industry 4.0 require increasingly faster design and implementation of robotic industrial process such as welding, milling, painting or coating. In Poland, many plants still offer such services in short production runs which means they often needs to reprogram robots so they can perform new tasks.

To support entrepreneurs, the technology of digital twins can come to the rescue. This are virtual copies of real machines performing real tasks. Their use at many levels improves the operation of an industrial plant and, importantly, also enables quick retooling of robotic production lines and adaptation to market needs.

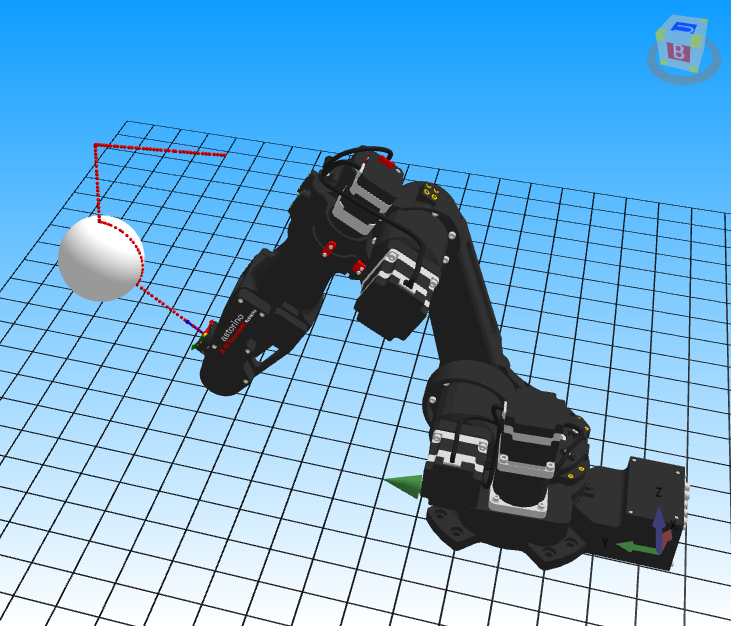

The digital twin is a virtual workspace that mirrors a real object. This enables the creation of 3D model of both the machine and the part it process, as well as the simulation of the process itself. This can be achieved by using a scanner and/or by manually entering the parameters of both object into the system and defining the type of tasks to be performed. . As a result, machining processes can be simulated and viewed as animations on a computer screen.

What are the benefits of a digital twin?

Lest start with the first group. At design stage, when an idea emerges for how to carry out, for example, the machine of a given part, the use of digital twin oofers the following benefits:

The digital twin in robotization:

- Allows to relatively quickly check whether a new task can be completed, without incurring implementation costs

A technologist or engineer designing the process can run its simulation and check how the robot arm moves – whether this is the most efficient movement and whether there is no risk of collision with other objects. Any potential errors can be easily corrected without incurring any costs.

- Enables performance estimation before production begins

Launching a robotic process using a digital twin allows simulation of raw material and energy consumption at any time, estimation of the machining speed of individual parts, and thus allows estimation of the process’s effectiveness operationally and also economically.

- Allows for offline robot programming

Traditionally, robots are programmed using a so-called teach pendant – a panel connected to the machine, which allows programming sequences of movements either directly or via computer and dedicated software. However, the learning process is much easier with a digital twin. Thanks to its interface, it is possible to input into the system the motion trajectories of the robot arm and the paths the tool is to follow – whether in welding, milling, or painting to achieve the desired result.

The second group of benefits focuses on process optimization, and these benefits are:

- The ability to improve the operation of the real system through simulations of modifications made on the digital twin

If a technician determinates that a certain part of the process is inefficient, they can run a series of simulations on the digital twin to show which type of process implements yield the best results. Only in the next step will they modify the robot’s software to implement these changes in reality.

- The ability to collect and analyze data about the operation of the real system

Based on this data, the technician is able to adjust the robot’s operation to make it more efficient.

What are the challenges of using a digital twin?

Creating the relationship between the object and the twin

A digital twin functions better the more accurately it reflects real object and processes. Therefore, the challenge is both creating the 3D model of machines and simulating the process, as well as constantly calibrating it. Solutions such as Touchsensing help with this by quickly determining the position of, for example, a processed detail in the real environment and updating its representation in the digital twin.

Training the digital twin operation

Despite a considerable degree of autonomy, a digital twin needs an operator. A key challenge is training a person with extensive knowledge of the process to operate it. Only then will the individual stages be properly reflected, and optimization conclusions will bring positive effects.

Creating autonomous digital twins

Thanks to the development of artificial intelligence and machine learning systems, many functions of digital twins are becoming automated. The challenge for factories using this technology is to design processes in such a way that they can be partially or fully controlled by the digital twin without human involvement.

Who is the digital twin of robotic process for?

This solution is primary for companies follow Industry 4.0 trends and are aware of new challenges. Not only large companies use this type of solution, but also small manufacturing. Factories involved in low-volume production will certainly benefit from implementation. However, since today all enterprises face market variability, it becomes increasingly important to use tools that allow quick adaptation to these changing needs. The digital twin is one of the most important solutions of this kind.