Handling Robots – automation of dexterity

Tasks requiring delicacy and precision related to gripping, transferring and arranging are increasingly performed not by humans, but by robots. Piotr Kaczorowski, an industrial robot specialist at ASTOR – about the benefits of using such machines. Interview by Katarzyna Szkopek.

Let’s start with a definition, what is handling?

These are process involving the transfering, manipulating, and rotating of parts in the production process , for example, to prepare or deliver them for matching, as well as handling finished products in internal transport, packaging, or palletizing. Handling – in the literal translation it means manual work requiring some dexterity. Handling can include servicing the ends of production lines, conveyor belts, stacking processes, layering (tiered stacking), or dosing. In all these applications, robots equipped with appropriate tools or grippers are increasingly proving effective.

When does using robots in handling make the most sense?

They have a wide range of applications. Limitations may include the technology (the tools that can be mounted on the robot arm) and safety requirements. The rest depends solely on imagination, needs, and, of course, economic considerations. The specific use of a robot in handling must bring benefits If we have a production process that can be described as 3D (dirty, dangerous, demanding), then automating such a process can be a good idea.

However, it is worth asking whether we want to implement a specially designed machine or a robot. The former will likely be faster, more efficient, and sometimes cheaper. However, a robot will be definitely more universal. In situations of changing market needs, a robot ca be easily adapted to the new tasks.

When the production of the part for which we purchased a specialized machine comes to an end, adapting it to a new task can be time-consuming and costly. A robot, on the other hand, can always be given a second (and even next) life.

In which industries in Poland do handling robots plays a key role?

The largest user of robots in Poland but also in the world is the automotive industry. In Poland, handling robots are also widely used in the broader metal industry, for example, in the operation of CNC machine, as well as in environments where working condition are extremely difficult for humans, such as in heavy industry, metallurgy, and forging. Handling robots are also used in the furniture industry. Additionaly, many manufacturing plant s- regardless of the sector – use them for various other handling-related tasks.

What are the characteristics of modern robotic solutions in the area of handling systems?

The most important feature of such systems is flexibility. Robotic system generally excel at performing repetitive, unchanging tasks. However, their ability to be modified means they can also be continuously adapted to new needs and shifting market demands. Nowadays, it’s rare for a product to be manufactured in an unchanged form for more than 10 – 15 years. In the case of smartphones, for example, new models are released every year – or even several times a year..

The most important feature of such systems is flexibility. Robotic systems generally excel at performing repetitive, unchanging tasks. However, their ability to be modified means they can also be continuously adapted to new needs and shifting market demands. Nowadays, it’s rare for a product to be manufactured in an unchanged form for more than 10–15 years. In the case of smartphones, for example, new models are released every year or even several times a year. Modern robotic handling systems must therefore be easily retrofittable and flexible so that they can be adapted to new production challenges.

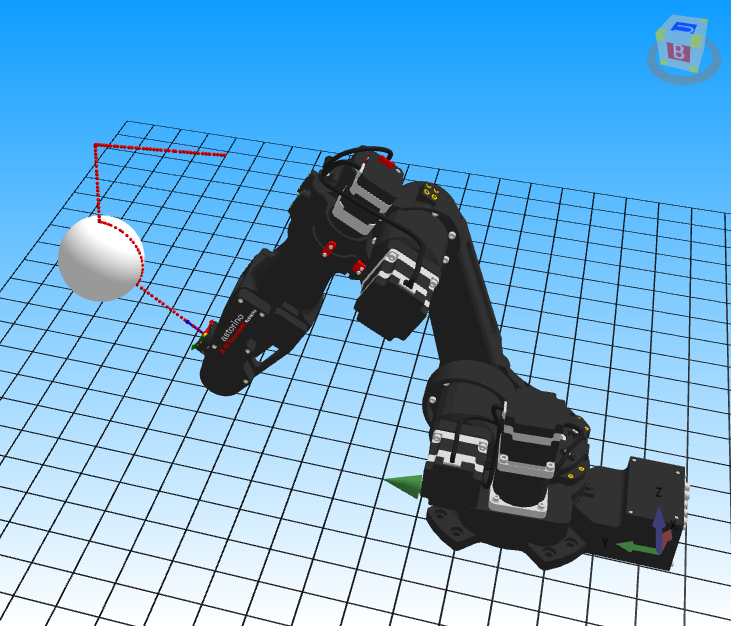

This means the ability to easily replace grippers or tools, load a new recipe, or quickly teach the robot new movements to allow it to work with a different product. If a digital twin, a virtual copy of the robot is used, retooling doesn’t cause downtime, since the robot’s movements can be programmed in the virtual environment. . The most advanced systems can also learn in real time: they observe the work area using various sensors, respond to changes in the environment, and adjust to new conditions.

How does robotization impact handling process in manufacturing plants?

When a robot replaces a human, these processes definitely become more repetitive. A machine doesn’t have “bad day” or its work does not depending on the seasons or t time of the day.Even if an error occurs at the beginning of the process, it will also be repeatable, making it easier to detect and eliminate.

What benefits and saving can companies achieve through the use of handling robots?

In many cases, using robots brings reputational benefits. Some clients even require that part of their partners’ production be automated. Otherwise, they may be reluctant to enter into cooperation.

Another advantage is more tangible. Constantly rising wages in the corporate sector mean that the ROI of investments is growing and the payback period is getting shorter.

There’s also the benefit of employee satisfaction. When robotization is well thought out and clearly communicated, the introduction of robots allows people to move away from monotonous, repetitive tasks and take on more ambitious roles, gaining new skills in the process. It’s also important to remember that not everything can be automated, meaning there will always be work for humans – for example, in preparing short-series versions of a product.

What are the main trends in the use of handling robots in Polish manufacturing plants?

Most of all, more and more small companies are beginning to automate their production lines. They recognize the need and see the benefits. In larger factories, there is an increasing demand for robots that collaborate with humans (such as cobots), although ensuring safety still remains a major challenge. Another trend is that robots are becoming increasingly “smart” thanks to sensors and artificial intelligence. With vision systems and neural networks, they can, for example, recognize objects with specific properties and move them to designated locations. While transferring objects, they can also perform visual inspections, assess quality, or sort products.

What technical or organizational challenges do companies most often face when implementing robots in the handling area?

The first organizational challenge appears even before the robots are introduced. Due to certain demographic trends, there is a lack of employees willing to take on difficult, repetitive tasks. On the other hand, when the idea of implementing robots is presented, there is often staff resistance to change and fear of losing their job.

These concerns often stem from a lack of information, which makes developing good internal communication and creating a training program crucial. If a company has never had a maintenance or automation department before, it’s necessary to either hire people with the right skills or train existing staff. It’s also important to clearly communicate the vision of robotization within the company. If employees don’t understand its purpose, it can result in a lack of engagement or even active resistance.

Another key challenge is maintaining safety. It’s essential that information about safe ways of working with robots and safety guidelines for operating near them is widely available and well understood by all employees.

What innovations or technologies currently have the greatest impact on the development of robotics in handling on the Polish market?

Many factories are now showing strong interest in sensors that can be integrated with robots, such as 2D and 3D cameras, often supported by artificial intelligence. These systems enable faster changeovers and simplify industrial processes. They also make it possible to implement applications for so called bin picking, where randomly placed parts are retrieved from containers. Automating this process helps avoid situations where the robot’s movements pose a danger to nearby human workers.

The second trend is the increasingly common collection of data from robots. These machines are connected to industrial networks, allowing for performance monitoring. Tracking a robot’s operating parameters also helps prevent breakdowns. If the system detects increased power consumption on one axis, it could signal a higher likelihood of failure, possibly due to a worn gear or brake issue. The data sent to the system allows early detection of anomalies and helps avoid unplanned downtime.

What skills should an employee have to operate and maintain handling robots?

Handling robots are not unique in this regard. Operating any type of robot requires good spatial awareness, allowing the operator to visualize the machine’s movements. Other useful traits include interdisciplinary knowledge: understanding of mechanics, pneumatic systems, sensors, as well as databases and general programming skills. Familiarity with robot accessories and industrial network systems is also valuable. The skills listed are desirable, but not always necessary.

Sometimes, a short training course is enough to learn the basics of robot operation. Skill gaps can a challenge during robot implementation, but they are not an insurmountable barrier. That’s one of the reasons why the number of these machines in Polish manufacturing plants is expected to increase.