How to plan expansion using new solutions

Two robotic welding cells as the next step toward development and international expansion, using the example of the company Perfopol.

Perfopol, founded in 1990, is a company operating in Starachowice with entirely Polish capital, and today it is a leader among manufacturers of perforated sheets and drawn meshes — in Poland and Europe. It also engages in the creation of steel structures and comprehensive metal processing. For 35 years the company has been continuously investing in modern technologies, automation, and team development. Today it employs nearly 300 people. The company delivers solutions for almost every industry, from construction, architecture, and industry to recycling, agriculture, and modern technologies.

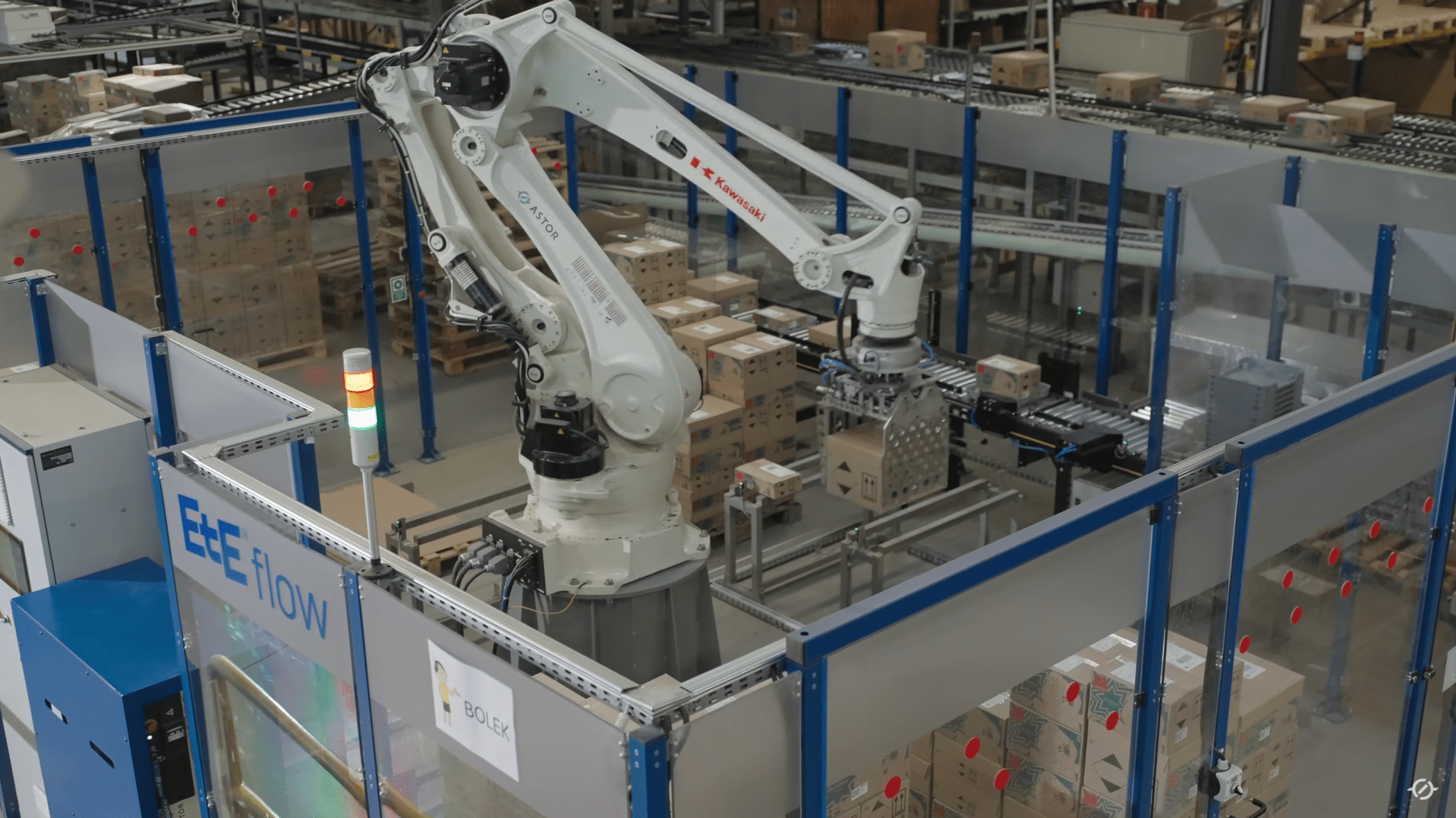

With the aim of optimizing processes and continuously increasing efficiency, Perfopol’s management decided to launch two robotic welding cells, allowing them to better take care of execution precision and the highest quality.

Robotics, automation and innovations allow us to stand out and constantly raise the quality of services. Investing in robotic welding cells was a natural step. Thanks to it we shorten production time, gain repeatability, precision and maintain the highest technological standards,” says Rafał Chromiec, Operations Director at Perfopol.

The key partner in the investment became ASTOR – a supplier of intelligent technologies for industry in Poland and Central and Eastern Europe, operating for over 35 years in intralogistics, automation, digitalization and robotics of production processes, supporting enterprises in the transformation toward Industry 4.0. The direct implementation of the investment was carried out by VELOWELD – a Polish manufacturer of advanced welding cells.

Two Stations, Two Technologies

In Perfopol and other similar plants, the welding method is chosen based on the types of parts. For those made from perforated sheets, which require high precision, the so-called TIG (Tungsten Inert Gas) method is used, which uses a tungsten electrode to provide better weld quality. For larger structures where precision is not as critical, the MIG/MAG (Metal Inert Gas/Metal Active Gas) method works better, using a consumable electrode.

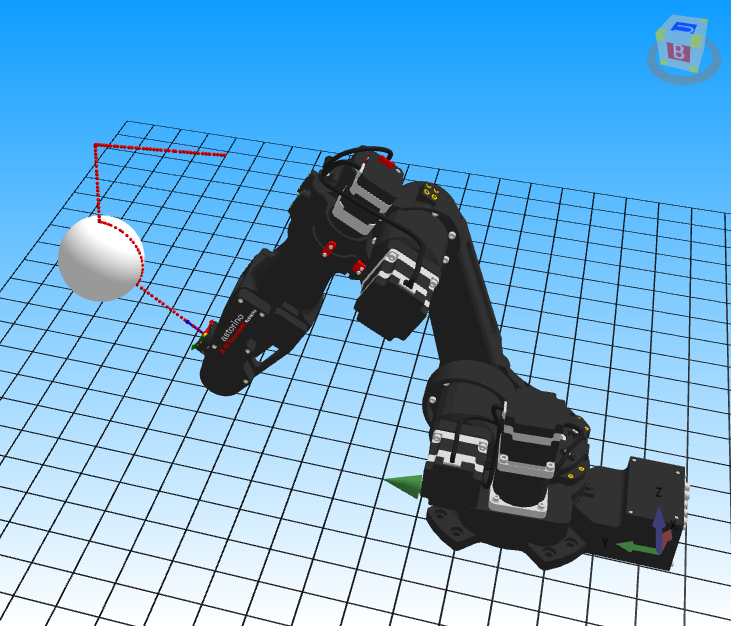

The first station implemented at Perfopol operates with TIG technology and was built on a single compact frame, which enables quick relocation in case of changing production needs. The station includes: a Kawasaki Robotics RA series robot, two positioners and a Fronius welding power source. Welding in this technology places strict demands on repeatability of clamping and precision of part execution. After meeting these criteria, high weld quality and repeatability were successfully achieved, regardless of size or production batch.

The second station is designated for MIG/MAG welding. It is equipped with a Kawasaki Robotics BA series robot, two positioners, a track and a Fronius welding system. The biggest challenge in its design was the optimal use of the limited production hall space (a narrow bay), while at the same time ensuring the maximum working range. Thanks to a bespoke approach to the project, it was possible to create a station that fully meets all functional requirements and assumptions.

Implementation Process and Benefits

Delivery of the stations and on-site assembly went quickly and smoothly because all applications were thoroughly verified before leaving ASTOR. At the stage of selecting the welding technology, tests were carried out on samples provided by Perfopol to ensure they met all quality requirements. After the stations were commissioned, ASTOR conducted comprehensive training for operators and programmers. The skills acquired during the training allow for independent programming of new parts and training of additional personnel without the need to involve external specialists, because the operation of the robotic stations is simple and intuitive. Investing in robotic welding stations and commissioning them resulted in a dramatic leap in efficiency. Elements that previously required a full day of welders’ work are now completed in just two hours with full repeatability and the highest quality.

The benefits of the implementation also align with Perfopol’s vision for company development, and the robotic welding cells themselves help realize this vision. Although Perfopol today is a market leader in Poland and one of the leading manufacturers of perforated sheets and meshes in Europe, the company’s ambitions reach much further. Perfopol’s goal is to strengthen its position in international markets and join the ranks of the world’s industry leaders with solutions that combine precision, innovation and reliability.