Robots as support for the brewing industry

Recently, beer consumption has been declining, , partly due to the rising costs of producing this beverage. One way to reduce these costs could be through the implementation of robotics.

Although the summer season, as usual, brings a certain rebound, the brewing industry has generally been facing challenges for some time now and for several reasons. Firstly, because beer sales are declining.

In 2023, Poles drank 30.555 million hectoliters of beer, which translates to approximately 6.111 billion half-liter bottles or cans. Compared to 2022, consumption dropped by over 6%, or nominally by 200 million liters , that is, 400 million bottles or cans , according to the Union of Brewing Industry Employers – Polish Breweries (ZPPP-Browary Polskie).

Beer sales in Poland have been declining for five years, but the drop in 2023 was the steepest yet. Back in 2018, Poles consumed around 40 million hectoliters of beer. The Union points to the cumulative effects of the pandemic, the war in Ukraine, and inflation as the main causes behind the rising production costs. In 2023, sales decreased in almost all market segments, driven in part by an average beer price increase of 15.2%. The largest decline was recorded in the premium and ultra-premium segments (down 14.6%) as well as in the economy segment, which includes the cheapest beers (down 10.0%).

-

-

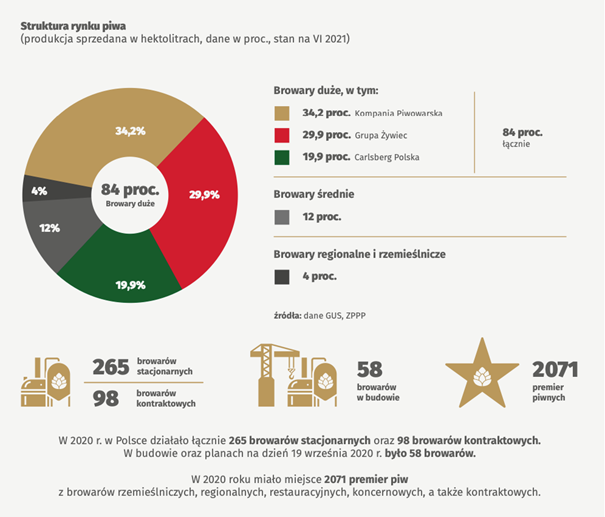

- Structure of the Beer Market

- (Production sold in hectoliters, in %, as of June 2021)

- Large breweries – 84%, including:

- Regional and craft breweries – 4%

- Source: GUS, ZPPP

- 265 stationary breweries

- 98 contract breweries

- 58 breweries under construction

- 2071 Beer Premieres

-

In 2020, there were a total of 265 stationary breweries and 98 contract breweries operating. As of September 19, 2020, an additional 58 breweries were under construction or in the planning stage.

In 2020, there were 2,071 beer premieres from craft, regional, restaurant, corporate, and contract breweries.

An additional burden for the brewing industry is the high excise tax. Since 2022, excise rates have been increasing on alcoholic beverages, tobacco products, tobacco for heating, and novel products. According to the schedule adopted for 2023 – 2027, as of January 1 2024, the excise tax has once again increased on ethyl alcohol, beer, wine, fermented beverages, and intermediate products – by 5%. Even before this, Poland already had a high excise tax compared to other European countries, higher for example, than in Germany, which is the largest beer producer on the continent. For the brewing industry, a high excise tax means higher costs of bringing the product to market.

Besides declining consumption and high excise taxes, breweries are also facing staff shortages, but this challenge shared across the entire manufacturing sector. This is due to demographic changes: older generations are retiring, and there is a lack of young people willing to work in production facilities.

Solution to overcome these challenges and reduce production costs may be the use of industrial robots. These robots can perform a variety of tasks, including handling, packaging, palletizing, and intralogistics. Let’s take a closer look at the areas in which robots can be most useful in the brewing industry and where they can contribute most significantly to reducing production costs.

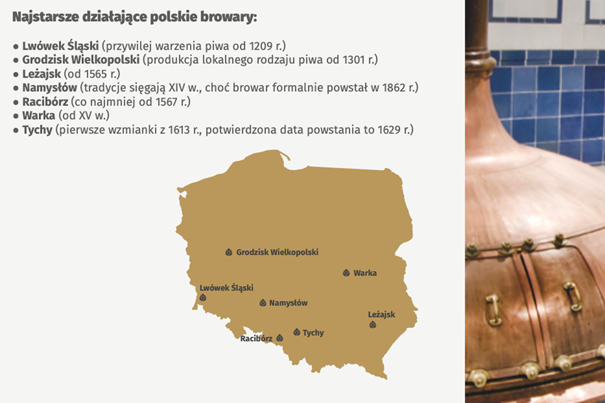

The oldest operating Polish breweries:

- Lwówek Śląski ( privilege of brewing beer since 1209 )

- Grodzisk Wielkopolski ( the production of local beer since 1301)

- Namysłów ( brewing tradition dates back to the 14th century, although the brewery was officially established in 1862)

- Racibórz ( beer has been brewed there since at least 1567)

- Warka (brewing tradition since the 15th century)

- Tychy (first records from 1613, confirmed founding date 1629)

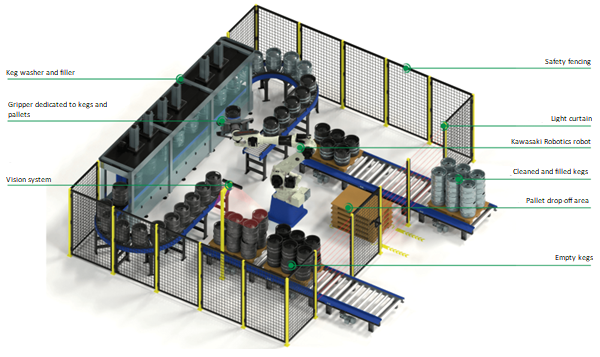

Supporting the process of filling empty kegs

Small and medium sized breweries, which are growing in number in Poland, often create unique recipes based on regional traditions. Due to their relatively small production scale, they often don’t have their own bottling lines. Beer is poured into kegs, and distribution is handled through bars and restaurants. The empty kegs are returned to the brewery, where they are unloaded, washed, and refilled. For workers, handling and unloading kegs is physically demanding and strenuous. A 50 liter keg can weigh over 11 kg even when empty.

This is where robots equipped with vision systems can assist people. Kegs returned from restaurants are stacked on pallets, often unevenly and at various angles, making them difficult for a simple automated system to handle. A robot with a vision system identifies the position of each keg and guides its arm to pick them from the pallet accurately and then place them on a roller conveyor, which then transports them to the washing and refilling station.

After transferring all the kegs, the robot place the empty pallet with its gripper in a designated drop off area with a pallet buffer or directly onto a roller conveyor, where cleaned and refilled kegs are later palletized. Once the cleaning, disinfection, and refilling process is complete, the kegs are moved via conveyor to the pickup point. The robot places a pallet on the conveyor and stacks the full kegs layer by layer. During this step, the keg is rotated 180 degrees again to ensure that the final product is delivered to the customer in the correct position. The kegs are then placed on pallets and transported by forklift to delivery trucks, which distribute them to restaurants.

Palletizing plastic crates with beer bottles

In larger breweries, where bottling lines are already there, robots can also significantly speed up and streamline the process, for example, by efficiently palletizing plastic crates filled with beer bottles. In the example shown below, two palletizing robots from Kawasaki Robotics are used: the CP180L and the CP500L. Although the two models have different payload capacities, they share the same shape and size. Both robots have a reach of 3,255 mm. In the video, the CP500L model, with a maximum payload of 500 kg, places 9 crates on a pallet at once. Meanwhile, the CP180L model, with a maximum payload of 180 kg, palletizes 3 crates at a time.

Robotic Automation of bottle handling and crate palletizing – example from the German Brewery Westheimer

The example below demonstrates how a robot can be used to automate the loading and unloading of bottles from conveyors. In the solution implemented at the German brewery Westheimer, Kawasaki Robotics BX200L robots were used.

The robot picks up eight crates with empty bottles from a pallet and transfers them to a roller conveyor. The crates are transported to a station where the bottles are removed from the crates and transferred by the robot onto a separate conveyor. The crates then proceed to a washing station. The bottles are also sent to a station where they are automatically washed and old labels are removed. Then, the roller conveyor carries the bottles to a quality inspection station, and then on to filling and capping.

In the next step, the filled beer bottles are sent to a labeling machine. Once labeled, they are transported to a station where the robot picks up 40 bottles at a time and places them into two crates. The loaded crates are brought to the robot station, where a special gripper enables the robot to lift eight crates at once and place them on a pallet. It stacks multiple layers of crates, and the completed pallet is then transported to the warehouse.

The system is equipped with a gripper exchange station, which allows for quick adaptation to product changes and increases production flexibility. The robot palletizes at a rate of 1,200 crates per hour, with the possibility of increasing efficiency by 25%. The Kawasaki Robotics CP500L robot has a payload capacity of 500 kg, a maximum speed of 900 cycles per hour, a reach of 3255 mm, and a palletizing height of 2200 mm.

Palletizing and Transporting Cartons with Finished Products

Robotic automation also increases the efficiency of the palletizing process through the use of an advanced safety system. The example shown in the video features a Kawasaki Robotics RD080N robot, which palletizes loaded cartons weighing up to 50 kg. Pallet exchange is carried out without stopping the robot, reducing unnecessary downtime. The robotic station presented achieves a palletizing output of 720 loaded cartons per hour.

Benefits of using robotics in the brewing industry

- Reduced production costs

- Increased production efficiency

- improved workplace safety

- greater production flexibility

These benefits related to process also have a business dimension: lower costs, higher revenues, and more efficient resource management, which can at least partially mitigate the effects of the challenging market conditions currently faced by the brewing industry.

How beer is made – The importance of brewing

When we talk about beer brewing, we often mean the overall production process of this beverage. In a narrower sense, the term refers specifically to boiling the so called wort, which results from filtering the mash in a special brew kettle with the addition of hops.

In Polish, the word used to describe the process of producing an alcoholic beverage, specifically beer is “warzenie,” which originates from old Polish and literally means boiling, or keeping food or liquid at a boil. After being boiled and cooled down, the wort is inoculated with yeast and undergoes fermentation, which leads to the creation of beer. The fermentation and maturation processes take place in fermentation rooms and lager cellars, or in modern fermenting and aging tanks. The finished beverage is then filled into kegs or bottles.