Industrial computers - what are they and why do we use them?

From this article you will learn:

- what an industrial computer is,

- what are the differences between industrial computers and classic office computers,

- what are the types of industrial computers.

Computers are everywhere today - and they are practically irreplaceable. There is a huge wealth of solutions on the market with different capabilities and purposes. Today we will look at a special type of these devices - industrial computers.

What is an industrial computer

Industrial computers (Industrial PC - IPC) are reliable and powerful devices, allowing them to work in harsh industrial conditions. Among other things, they are characterized by high resistance to dust, dust, water and shock. In addition, they are adapted to work in extremely low and high temperatures.

From a software point of view, IPCs are no different from ordinary home or office PCs. They can run standard operating systems and applications. They are distinguished only by their industrial design, ensuring high reliability and trouble-free operation regardless of conditions.

Industrial computers can be equipped with processors of varying performance - from economical solutions such as Intel Atom or Intel Celeron to the most powerful Intel Core i5 and Intel Core i7 processors. The advantage of the former is lower power consumption, which additionally translates into lower operating temperatures (and thus lower cooling requirements). High-performance processors, on the other hand, are essential for more complex systems, such as advanced SCADA applications.

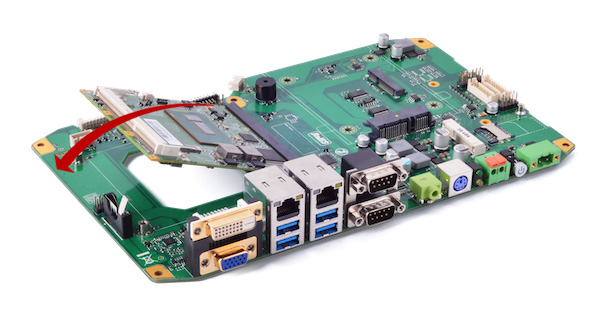

Industrial computers can, of course, be connected to the Internet, as well as - via a variety of communication ports and protocols - to a variety of devices, such as PLCs. IPCs are equipped with serial and Ethernet ports - the number of ports depends on the specific model. In addition, many computers have Mini PCI or PCI expansion slots, so you can expand the device with additional ports.

Most models (including, of course, all BOX computers) have the ability to connect an external monitor through one of the ports: HDMI, VGA or DVI. We will also connect to them (via USB ports) peripheral devices such as a printer, barcode scanner, industrial scale, mouse, keyboard or memory stick. In addition, it is worth mentioning that IPCs are often equipped with Audio connectors and even ports for PS/2 keyboards and mice.

Types of industrial computers

Two basic types of industrial computers can be distinguished: panel and BOX. A panel computer is integrated with a monitor - it has a built-in matrix that acts as a screen. Such a matrix is most often touch-sensitive, so you can operate the device with the touch of your fingers, and a keyboard and mouse become unnecessary.

Panel computers offer different types of screens. First of all, different sizes are available, which, as in the case of ordinary monitors or televisions, are defined by the diagonal length of the screen, expressed in inches.

In panel computers we encounter two types of display: a resistive or capacitive matrix. The first type is suitable for computers operated on production halls, where operators use gloves, because they can be operated with gloves. The second type of display - capacitive - provides better image quality, and additionally supports the multi-touch function known from smartphones. It gives you the ability to operate the device by simultaneously touching more than one point on the screen. Unfortunately, this type of screen cannot be used with gloves.

Panel computers are mainly used for visualization, reporting or data analysis systems.

The second variant is BOX computers. These are also industrial design devices, but without a screen. Their main advantage is that they can be built into cabinets. As a result, they take up less space and are additionally protected from damage. However, you need to connect an external monitor or industrial touch panel to them. It is worth mentioning that there is no limitation here in terms of the size of the monitor to be plugged in. On the one hand, you can plug in a small monitor, and on the other - if necessary - a large TV.

It should also be mentioned that industrial touch monitors are also available on the market. These are screens that resemble panel computers in appearance and functionality, but need to be connected to a BOX computer or even to a standard office PC (if it is placed in an isolated room, for example). They are characterized by analogous resistance to environmental factors as in the case of IPC. Using such a monitor in combination with a BOX computer, we get the equivalent of a panel computer, but such separation of functions into two separate devices can sometimes prove a useful option.

Differences between industrial computers and classic office computers

Since an IPC is simply a computer, why buy a more expensive industrial device if an office model with the same parameters will be clearly cheaper?

One of the biggest problems for a manufacturing plant is downtime caused by failures. They always generate large losses, and can also cause other damage (such as technological). Therefore, it is obvious that all equipment working on the production line must be resistant, durable and failure-free. And as I mentioned above - this is the main distinguishing feature of industrial computers. The production hall is definitely not a friendly place for an office PC, which is a delicate device and sensitive to harsh conditions.

What factors are industrial computers resistant to? What is worth paying attention to?

- Temperature operating range – computers can operate at different temperatures. Some devices are equipped with heaters inside the chassis, so working in extremely low temperatures will not cause major problems. When it comes to high temperatures, computers are equipped with efficient passive cooling systems that will help keep the device at the right operating temperature, not allowing it to overheat even at temperatures in the 60°C range.

- Water resistance – industrial computers are most often fully resistant to all kinds of splashes, flooding, and some of them to complete immersion in liquid. The IP parameter, corresponding to the waterproof class, determines how resistant the device will be. Some companies also offer splash-proof industrial accessories, such as a mouse or keyboard. They owe their resistance to the special rubber they are covered with.

- Dust and dust resistance – most computers are equipped with passive cooling. Thanks to it, the device becomes a tightly sealed structure, resistant to the ingress of dust into the case. It is worth mentioning that one of the most common causes of failure of computers not equipped with passive cooling is the failure of fans. This is caused, of course, by the lack of resistance to dust (open design).

- Shock resistance – in industrial settings, it is additionally important for a computer to be resistant to all kinds of shocks and vibrations. To meet this task, computers most often have a suitably reinforced design and are equipped with durable and fast SSD drives.

- Resistance to electromagnetic interactions – some industrial computers are resistant to electromagnetic interactions. For verification, check the electromagnetic compatibility (EMC) provided by CE/FCC certifications.

So it's easy to see that no office computer will provide us with even a fraction of the level of reliability as an industrial device. Of course, this involves a higher price of industrial computers, but here it is definitely not worth saving. The cost of frequent failures of a cheap computer will very quickly exceed the saved price difference.