Plug in and start production. Robotic welding with VELOWELD

Przemysław Drzymała, Director of the VELOWELD Welding Competence Center, and Szymon Habecki, Implementation and Engineering Team Leader, talk about robotic welding, the VELOWELD brand, and its offer for clients.

The VELOWELD brand appeared on the market in 2024, but the topic of robotic welding has been present at ASTOR for many years.

Przemysław Drzymała: Yes, we’ve been active in the welding industry for a long time. We’ve been developing robotic welding competences within our team. At first, we operated as a welding competence center. Now, we are a separate business unit within ASTOR, developing this market. We have our own brand.

Where does the name VELOWELD come from?

PD: “Weld” obviously refers to welding. And “velox” is Latin for speed, dynamism. We want to be “velox”. We offer ready-made, almost off-the-shelf solutions, which is quite uncommon in this market.

Szymon Habecki: I believe we’re the only supplier in Poland capable of delivering a fully operational robotic welding cell—from receiving the order to igniting the arc—within just two weeks. That’s a major differentiator of VELOWELD.

PD: The VELOWELD team focuses exclusively on welding. We wanted a banner we could carry across Poland first, then Europe, and eventually the entire world. That’s how the idea for our own brand came about. We want to highlight our speed and dynamism while building an identity for a team that does only this and specializes in it.

Where does VELOWELD currently stand on the market?

PD: We produce 35 to 40 welding systems per year, primarily for the Polish market. I think we’re now a significant player. It’s worth noting that we’ve built our position from scratch and grow our market share every year. We’re growing faster than the overall welding market in Poland.

You said “primarily for the Polish market.”

PD: We’re seriously thinking about international expansion. We’ve already contracted our first cell for a client in the United States, and it’s currently in production.

You mentioned your welding expertise earlier. Let’s talk about that a bit.

PD: Our team includes specialists with over 10 years of experience in the welding industry. We have certified welding engineers with International Welding Engineer (IWE) certification. We also have our own design team and on-site assembly crews. Our people handle everything—from designing the station, through construction, to commissioning.

SH: This year we opened a welding center in Gdańsk, northern Poland and a lab in Kraków, southern Poland. At both locations, we conduct welding tests, training for clients, and production of the welding stations.

PD: With these two locations, we can operate freely throughout Poland and easily reach every client. We’re very open to collaboration at every stage. We do prefabrication in-house, so if a client wants to visit and see the welding cell in progress—they’re welcome. They can come and test it.

SH: Thanks to both assembly-equipped locations, we can produce multiple stations simultaneously—close to our clients. Sometimes, we also produce stations from scratch directly in their facilities. Currently, we’re assembling robotic cells in parallel—two in our Gdańsk production hall and one in our Kraków facility.

So you produce a welding cell in Gdańsk or Kraków—and then what are the next steps?

PD: Our cells are modular, like built from blocks. After producing, commissioning, and testing, the cell is disassembled. We design them so they fit easily into a freight container. Then the station is shipped in that container to the client. We also travel there to reassemble the cell on-site.

If the welding cell fits in a container, it can be shipped to Wrocław—or overseas.

PD: Exactly. The container goes on a ship to the USA, we hop on a plane, and assemble the welding station over there. The location is never a problem. If a client wants the welding cell in Australia—we’ll go to Australia.

What makes VELOWELD cells stand out?

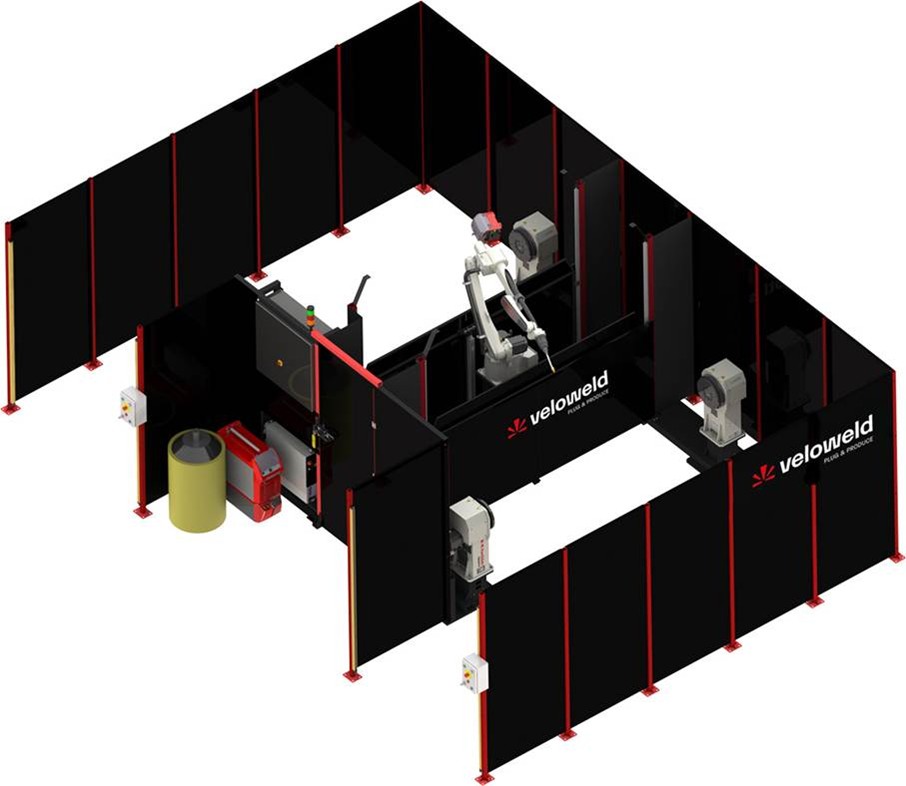

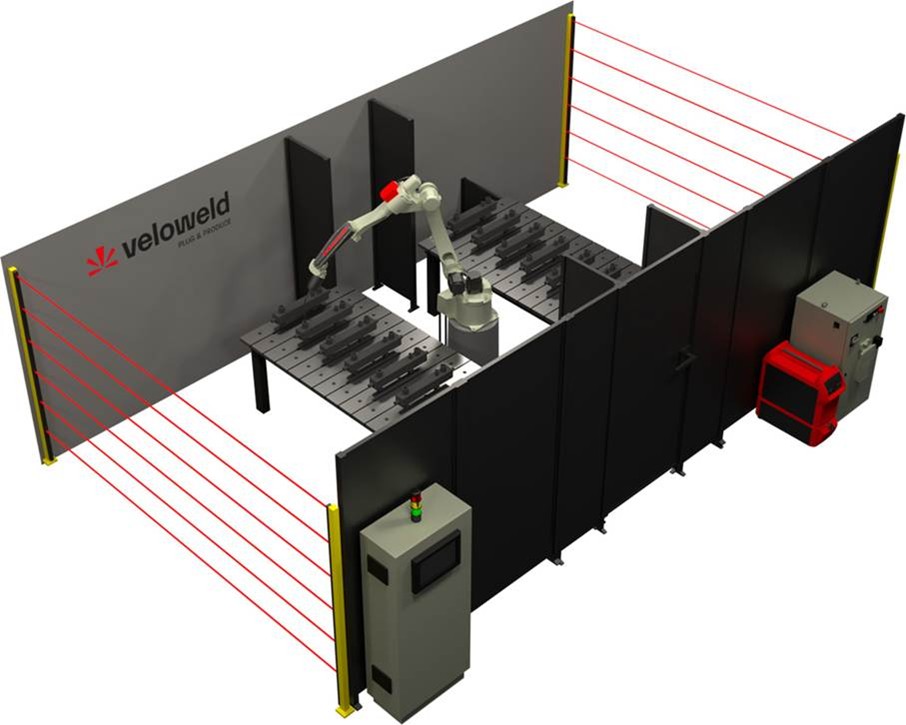

PD: I’d say our cells are premium. Our client doesn’t get an ugly unit made of cheap corrugated sheet metal. Instead, they receive a well-designed, aesthetic cell with custom branding, personalized software, full process visualization, and data access. We combine traditional robotics with custom software. We care deeply about quality. We deliver a premium product—at a reasonable price. The aesthetic and quality aspects are very important to us.

SH: Quality is how we want to differentiate ourselves. We produce welding stationsthat clients are proud to show off.

Who is your offer primarily aimed at?

PD: Anyone who needs robotic welding. But most of our clients are small and medium-sized companies. We’ve even installed robots in garage-like workshops. Clients appreciate our business model, which adapts to their needs. If a client can do part of the work themselves and only needs specific components—we adjust. We don’t insist they buy everything from us. That also means a limited budget doesn’t have to be a problem. Sometimes clients assume robotic welding is too expensive, but we find a way to make it feasible. We seek different solutions to grow the welding market.

You mentioned having off-the-shelf solutions. What does that mean for welding cells?

PD: We currently have three welding station configurations that Szymon can build with his eyes closed—in two weeks.

SH: We have a project portfolio that’s 100% repeatable—no need for redesign or rewriting applications. Right now, we’re shipping two such units—one from Gdańsk and one from Kraków. They’re truly ready-to-go products.

PD: We usually keep two such welding cells in stock. So yes—you can call it an off-the-shelf product.

SH: The client can buy something that’s already made. No need to wait for custom mechanical and electrical components. They get a ready product capable of producing their parts.

So if I walk in and say “I’d like a welding cell,” is it that simple?

PD: Almost that simple. You come in, we run a workshop to demonstrate how everything works. You bring your part and set it up on the cell. We write a welding application for you. In one day, you test the station—touch it, examine it, weld. If you want it, we pack it up the next day, and it can be at your site by day three.

But a ready-made welding cell is just one option. What if I have specific needs?

SH: Of course, the off-the-shelf cell is just one possibility. We can always customize the station—which we love doing. The standard package includes a welding robot with a welder and safety fencing that fits the client’s space. Everything else can be tailored. We can add a welding positioner to adjust part orientation and avoid awkward welding positions. We can select payload, number of axes, work area size. We offer welding tables, protective screens, and a travel rail of specific length. Our control apps are also customizable—like HMI panels with visualization, factory network integration, or ERP data sharing. We configure the welder both in hardware and welding processes. We help clients choose the right technology to get the desired results.

PD: Importantly, even fully customized welding cells are delivered fast. In Poland, a typical lead time is about three months. We only need three months when it’s a completely new, complex system. For standard setups, we aim to deliver within one to one and a half months. That’s very fast, but our experience makes it possible.

SH: Honestly, we’re talking about a handful of typical configurations—there’s not much new to invent. Sure, you can create an insanely customized welding station, but in practice, we work within six or seven setups—adjusting the positioner, type and size of work area, rail vs. stationary robot, HMI panel, or branding. We can also add fume extraction hoods with filter ventilation—also available on request.

Now we come to a crucial element—the training package provided with each cell.

SH: Training is an integral part of every robotic welding station we deliver. We introduce clients to welding technology, teach how to use the equipment properly, and most importantly—how to program welding applications with the robot. The training also includes tech support for welding specific parts. By co-creating applications and selecting welding parameters together, trainees can independently implement new parts in production. This approach brings extra value—reducing both time and costs of automating the welding of new products. If needed, we also assist in designing welding fixtures.

PD: It’s a bit like selling cars along with a driving course. Thanks to this, the client can hit the road after just three days – and manage everything completely independently.

So your goal is to transfer all the knowledge the client might need.

PD: We’re able to guide the client through the entire process of needs analysis and identifying what they really require, what configuration will work best for them. Also from an economic perspective – so they don’t overinvest. We provide all the necessary technical support. It’s very important for us that the client takes over these competencies and develops them internally. We understand that, in the beginning, they need a lot of our time and involvement – that’s clear. But over time, our role in supporting them decreases, because they are building a team that will handle everything just fine. And what’s important – they don’t need people with some unimaginable level of skills. All it takes is an open mind and a willingness to learn. We’ve taught people to write welding applications who didn’t even know what the internet was, but they did great because they were eager and open to learning something new. Of course, if someone has knowledge or experience, it’s easier – but not having a specialist background is not an obstacle.

SH: On the other hand, we’ve produced and delivered about 150 workstations, and only once did a client come to us who knew nothing about welding. The vast majority of our clients already weld – they do it manually – and they simply need to improve the process, automate it, increase efficiency or flexibility. That’s when they look for a welding robot.

PD: It’s also important to note that most of our clients are service companies – meaning, companies without their own product. Our business model is well suited to their needs. They should have these competencies in-house, be able to quickly write a new application, build a new jig, so that today they can weld a tank, tomorrow a hanger, and the day after a frame. They need an open, flexible machine to be able to produce different components in a short time. And having those competencies – which we teach them – allows them to stay competitive in this market.

SH: We’ve never delivered a cell without including training. You could say that at every client site, there’s always someone left who knows how to program the robot, who understands the technology, and will later know how to start welding a new product. But I want to emphasize that we don’t just show everything in a lab setting. We’re not afraid to get our hands dirty – we show up at the client’s site and work with them for a day, two, or however long it takes, so they know how to use the machine and write any application they come up with.

PD: This model works – it proves itself in practice. We already have over 150 implementations in Poland. Clients are satisfied because they can quickly feel that the investment pays off. Often, they later want to expand the workstation, gradually adding new jigs, new applications, more complex components, and so on. These cells stay alive and keep evolving.

Interview by: Mateusz Pierzchała